Your project is in the Middle Eastern desert, where temperatures hit 50°C (122°F). Or, it's in Northern Canada, where it's -30°C (-22°F) for three months straight.

In these conditions, a standard container isn't a house; it's a death trap. An uninsulated steel box becomes an oven or an icebox.

From my experience, 90% of all worker complaints on an extreme-climate site—from high turnover to low morale—can be traced back to a single failure: bad insulation.

Your energy bill for "Active" heating or cooling (running AC units 24/7) will be astronomical. Your real problem, however, is "Passive" protection. This isn't just a guide to insulated container homes; it's a field guide to choosing the right insulation material for your job site.

The "Active" vs. "Passive" Fallacy

Many PMs think: "I'll just install a bigger AC unit." This is the "Active" solution, and it's a TCO (Total Cost of Ownership) nightmare.

The "Passive" solution is the container itself. A well-insulated unit holds the temperature, meaning your AC or heater runs for 20 minutes an hour, not 60.

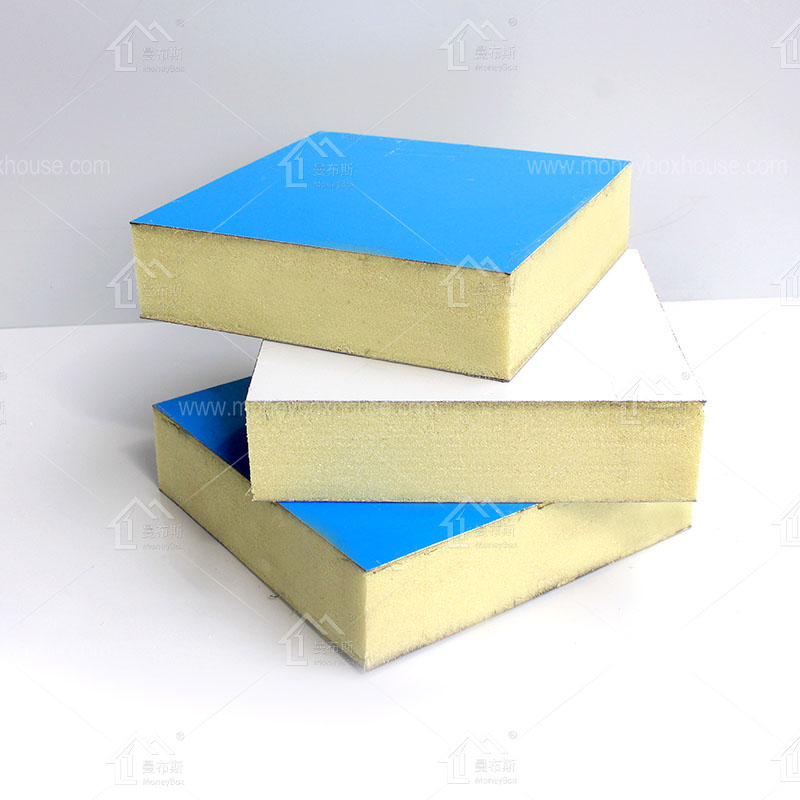

The key is the sandwich panel. This is the "skin" of your modular building, and it's where your entire climate-control battle is won or lost.

Material Deep Dive: Choosing Your Armor (PU vs. Rockwool vs. EPS)

As a manufacturer, we supply all three. Here is the blunt, no-sales-talk breakdown of what you actually need.

1. Polyurethane (PU) Panels: The Climate King

If your primary enemy is temperature, PU is your best-in-class solution.

PU (Polyurethane) is a high-density foam injected between two steel skins. It has the highest "R-value" (thermal resistance) per inch of any common material.

- Best For: Extreme cold (Siberia, Canada) or extreme heat (Middle East, Africa). A 75mm or 100mm PU panel provides incredible thermal efficiency.

- The Trade-Off: PU is typically the highest cost per panel.

- The Verdict: If your project is long-term (2+ years) in an extreme climate, the energy savings from PU will pay back the initial investment. It is the TCO champion.

2. Rockwool (Mineral Wool) Panels: The All-Rounder

If your concern is safety and sound, Rockwool is your spec.

Rockwool is made from spun basalt rock fibers. While its R-value is very good (better than EPS, not as high as PU), its true value lies elsewhere.

- Best For: Projects with strict fire codes or high noise.

- Fire Safety: Rockwool is Class-A non-combustible. For a high-density worker camp where fire risk is a major HSE concern, many large-scale EPC clients mandate Rockwool.

- Sound Insulation: It's a fantastic sound insulator. If your camp is next to generators, heavy machinery, or a processing plant, Rockwool-paneled dorms are the only way your night-shift crew will get any sleep.

- See the Product: Moneybox Glass Wool / Rockwool Sandwich Panels

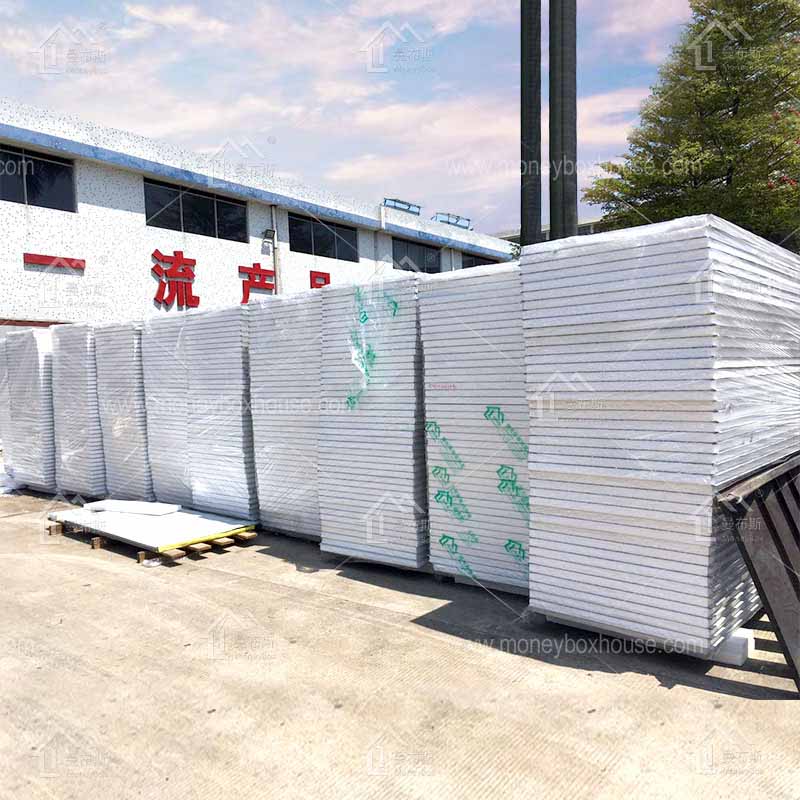

3. EPS (Polystyrene) Panels: The Cost-Effective Standard

EPS is the white beaded foam you're familiar with. It's the industry standard for a reason.

- Best For: Temperate climates or budget-driven projects.

- The Verdict: It provides good, basic insulation and is the most cost-effective option. It's the perfect choice for construction site housing in most of Southeast Asia, South America, or temperate Europe.

- See the Product: Moneybox EPS Sandwich Panels

At-a-Glance: Insulation Material Comparison

| Material | Thermal (R-Value) | Fire Safety | Sound Control | Cost |

| PU (Polyurethane) | ★★★★★ | ★★☆☆☆ (Fire-retardant) | ★★☆☆☆ | $$$ |

| Rockwool | ★★★★☆ | ★★★★★(Non-combustible) | ★★★★★ | $$$ |

| EPS (Polystyrene) | ★★★☆☆ | ★☆☆☆☆ (Fire-retardant) | ★☆☆☆☆ | $ |

Beyond the Walls: Don't Forget the "Leaky" Spots

A perfect wall panel is useless if the building isn't sealed. When specifying your insulated container homes for field work, you must also demand:

1. Thermal Bridge-Free Design: The steel frame itself can conduct heat/cold. A well-designed unit uses "thermal breaks" to stop the frame from transferring the outside temperature in.

2. Double-Glazed Windows: A single pane of glass will undo all your insulation efforts. Double-glazing is mandatory for any extreme climate.

3. Sealed Doors & Joints: All panel joints and door frames must have high-quality rubber seals to prevent drafts.

Conclusion: Spec the Right Panel, Win the Climate Battle

Don't just ask, "how much is a unit?"

Ask, "What is the R-value of your 75mm PU panel?" Ask, "What is the fire-rating on your Rockwool panel?"

As an experienced supplier of durable shelter units for oil field or mining camps, we know that the initial design specification is what determines your project's long-term operational success. Let us help you spec the right "armor" for your climate.

- Get a Quote for Insulated Container Homes

- See All Our Sandwich Panel Options

Frequently Asked Questions (FAQ)

1. What is the best material for prefab camp accommodation? For "best," we must define the challenge.

- Best Thermal: Polyurethane (PU)

- Best Fire/Sound: Rockwool (Mineral Wool)

- Best Cost: EPS (Polystyrene)

For most high-end mining or oil & gas projects, the choice is almost always Rockwool or PU.

2. How do you heat/cool a container home in an extreme climate? You use a passive-first strategy.

1. Passive: Use high-R-value insulated panels (PU or Rockwool, 75mm-100mm thick) and double-glazed windows. This does 80% of the work.

2. Active: Install a correctly-sized HVAC (Air Conditioning) unit. Because the unit is "passively" insulated, your HVAC runs far less, saving massive amounts on fuel for your site generators.

3. Do insulated container homes have mold or condensation problems? They can if not designed properly. Condensation (and then mold) happens when warm, moist inside air hits a cold inner surface (a "thermal bridge"). We prevent this by:

1. Using thick insulation to keep the inner walls warm.

2. Ensuring proper ventilation (air exchange), especially in ablution blocks and kitchens.

3. Using thermal-break designs in the steel frame.

4. What is an R-value and why does it matter? R-value is a measure of thermal resistance. The higher the R-value, the better the material is at stopping heat transfer. A high R-value means less heat gets in during summer, and less heat escapes during winter. It's the single most important metric for an insulated container home.